Specially designed for Molecular Sieve application it can be used effectively in dirty services. The ball movement off the seats allows a cleaning action of the ball surface thus eliminating the friction during opening/closing actions and allowing for reduced torque/thrust during operation.

GENERAL APPLICATIONS

Top Entry Rising Stem Ball valves are suitable for Molecular sieve dehydration, dryer switching, suction, and discharge isolation, heat transfer, flowlines, Emergency shutdown, etc.

MATERIALS OF CONSTRUCTION

Low Temperature and Low Alloy Carbon Steel, Stainless steel, Duplex and Super Duplex, Nickel alloys

APPLICATIONS

• UTILITY

• CORROSIVE & DIRTY

• LOW TEMPERATURE

• HIGH PRESSURE

TECHNICAL DATA

|

Design |

API 6D, API 600, ASME B16.34, ISO 14313, ISO 10423, ISO 17292 |

|

Design pressure |

ASME B16.34, API 600 |

|

Body wall thickness |

ASME B16.34, ASME VIII Div. I, ASME VIII Div. 2, ISO 17292, API 600 |

|

Face to Face |

API 6D, ASME B16.10 Long pattern |

|

Temperature range |

-196° to 600°C (-320° to 1112°F) |

|

Pressures range |

PN20 (ANSI 150) to PN420 (ANSI 2500) |

|

Size range |

DN50 (2″) to DN600 (24″) |

|

End connections |

ASME B16.5 ≤ DN600 (24″) Flanged RF, FF, RTJ MSS-SP-44 = DN550 (22″) Flanged RF, FF, RTJ ASME B16.25 Butt-Weld BW Clamp (HUB) |

STANDARD FEATURES

|

Construction |

One piece bolted bonnet |

|

Port |

Reduced bore, full bore or fully piggable |

|

Stem retention |

Anti blow-out stem |

|

Sealing |

Single seated bi-directional, with preferential flow direction, to avoid pressure trapped between the seats. Metal seated with Tungsten or Chrome Carbide coating; Soft seated with thermoplastic polymers (Nylon, Devlon, PEEK, PCTFE), special polymers upon request |

|

Leakage rate |

ISO 5208 rate A soft seated, rate B, C, D metal seated |

|

Operating Description |

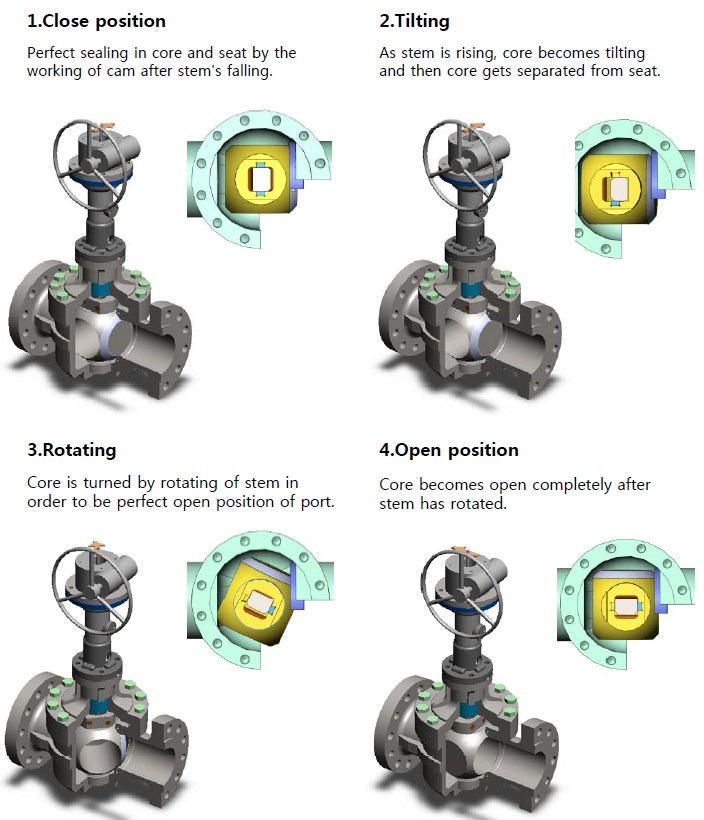

The movement of the ball tilted from the seat before starting the rotation eliminates the wear of the seat seal and allows for smooth movement and low torque. The same tilting movement when starting the opening allows for a cleaning flow all around ball surface; this flow automatically flushes the ball surface removing eventual dirt particles from the sealing areas |

|

Grease injectors |

Available on request on both seats and stem |

|

Drain / Vent |

Drilled and threaded connections for all sizes, Vents for sizes below DN |

|

Vent |

Drilled and threaded vent connections for sizes ≥ DN150 (6″) < DN150 upon request |

|

Lifting points |

Included for sizes ≥ DN150 (6″) or on valves of 250 kg min |

|

Support feet |

Included for sizes ≥ DN150 (6″) or on valves of 250 kg min |

|

Stem extension |

Available for applications in low/cryogenic temperature applications or for high temperature application |

|

Valve operation |

Handwheel, Gear box or Actuator with position indicator and locking device |

|

Material testing |

Pressure containing & controlling parts to EN 10204 3.1 Materials in Sour Service according to NACE MR0175, MR0103, ISO 15156 Non-destructive testing (NDT) to API 6D, ASME B16.34 |

|

Valve testing |

Hydrostatic & pneumatic testing to API 6D, ASME B16.34, ISO 5208 (other upon request) |

APPROVALS

|

Safety Integrity Level |

SIL 3 |

|

Fire Safe |

API 607, API 6FA, BS 6755, ISO 10497-5 |

|

Area Classification |

ATEX 94/9/EC |

|

Pressure Equipment Directive |

PED 97/23/EC |

|

Fugitive Emission |

ISO 15848/1, ISO 15848/2 |

|

Construction |

API 6D, API 6DSS |